If you’re looking for clear and comprehensive information about roll containers, you’ve come to the right place. In this FAQ guide you will find everything you need to know to understand what models are available, how to choose the one best suited to your storage and handling needs, and what accessories can make your work easier and more efficient. Roll containers are essential tools in many industries because of their versatility and practicality: find out how to make the most of them.

When is it worthwhile to use a Roll Container instead of a regular goods cart?

The Roll Container is the ideal choice when you need to move several packages at once, even of different sizes, in a safe, orderly manner and without the risk of falling. Unlike traditional trolleys, rolls have side walls that hold the load, often with the option of front closure or accessories such as shelves and straps.

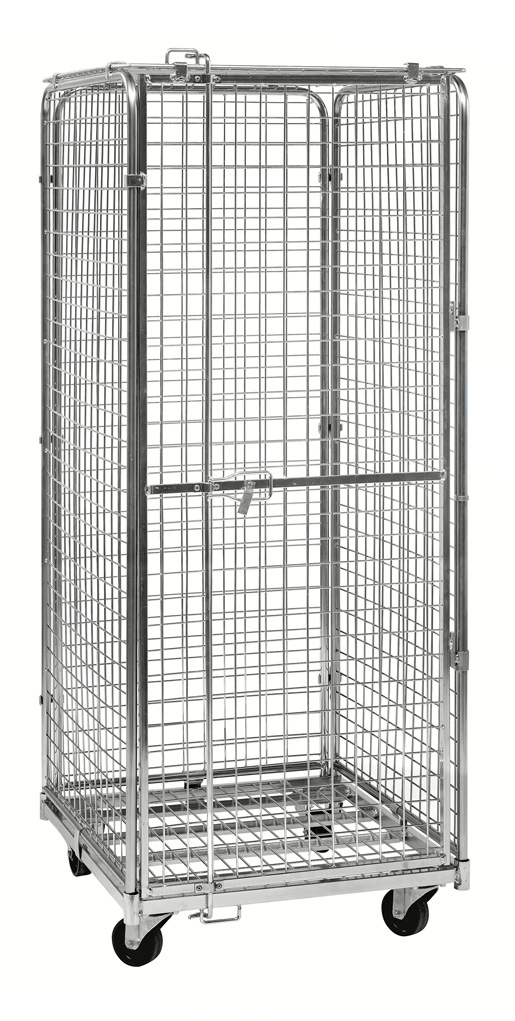

Features of a Roll Container

What are the standard dimensions of roll containers?

The most common standard size is 72×80 cm, because it represents the best compromise between load capacity, maneuverability and optimization of truck space. It is suitable for most uses in logistics and large-scale distribution.

However, there are also more compact versions, such as the 60×74 cm roll, designed for environments with small spaces, such as stores or narrow aisles. On the other hand, when you need to transport very large volumes, you can opt for the Jumbo models, which can go up to 200×100 cm.

How to evaluate the quality of a Roll Container?

To evaluate the quality of a Roll Container, it is essential to consider materials, design, and finish. A concrete example? In the ROLR Series, side reinforcements allow the roll to be used effectively even with only two sides, keeping the load stable during transport through the use of straps.

Another key aspect is the quality of the welds: Italiana Contenitori employs high-precision robots and skilled personnel to ensure solid and reliable joints over time.

Wheels play a crucial role: poor materials compromise smoothness, stability and safety. Better to choose quality wheels, perhaps with galvanized steel supports and ball bearings.

Finally, watch out for galvanizing: a good galvanizing should be uniform, bright and smudge-free to provide corrosion resistance even in wet or industrial environments. Low-quality galvanizing can compromise the overall durability of the roll container.

What materials are used to produce roll containers and what are the benefits?

Roll containers are made mainly of iron wire and bars, materials chosen for their strength and ability to absorb shocks and deformations without compromising functionality. The iron structure ensures durability even in demanding working environments.

The galvanic finish is another key element: it protects the metal from corrosion and gives the roll a clean, professional appearance, making it suitable for food or sanitary settings as well (in any case, food cannot come into contact with the roll container).

There are also models with a plastic base, which offer the advantage of being lighter, facilitating manual handling, and at the same time resistant to wear and tear, especially in environments where moisture or frequent washing could damage a metal base.

How much does an average empty roll container weigh?

The most compact models weigh around 28 kg on average, ideal for small spaces and frequent handling.

MAXI Security Roll Containers, which are more robust and have higher load capacity, can be up to 70 kg.

How many kilograms does a roll container carry?

The capacity of a roll container depends on the model and size. The Compact Roll can support up to 250 kg, ideal for light loads and tight spaces. The models standard, MAXI e Jumbo offer capacities of up to 600 kg, perfect for heavier loads and larger volumes.

What is the average duration of a roll container?

A well-maintained roll container can last even more than 10 years. Under normal use, this is the estimated average lifespan, but in reality a roll can be virtually eternal if used carefully and maintained regularly.

Another advantage is modularity: in case of damage, it is not necessary to replace the entire roll. It is often sufficient to replace only the damaged part, such as a wheel, wall, or shelf, thus reducing costs and waste. These maintenance tasks, which are very easy to carry out, can be done independently by the customer by purchasing the necessary spare parts.

Customized roll containers: is it possible?

Of course we do, especially with Italiana Contenitori. We control the entire production cycle in-the-house, from design to production which allows us to offer custom-made roll containers according to the customer’s specific needs. Our engineering department is available to study customized solutions, with modifications on dimensions, accessories, structure and functionality, to perfectly fit your business.

Using a Roll Container

How long does it take to assemble/disassemble a roll?

Assembling or disassembling a roll container is a quick and easy operation. For a standard model, it takes only 5-10 minutes. If it is a large roll or one with multiple accessories or shelves, the time can be 15-20 minutes at most. Due to the modular design, assembly does not require complex tools and can be done by one operator.

How to reduce the space occupied by empty rolls?

There are two main solutions. The first is to disassemble the rolls, an operation that takes only a few minutes for each: the sides, shelves, and bases are stored on top of each other, often using one roll left assembled to neatly hold all the components of the others.

The second, more practical and faster, is to choose a Nestable Roll Container, designed to fit one roll inside the other-just like shopping carts-so you can drastically reduce the space requirements without having to disassemble them.

Can I modify my roll according to the use of the moment?

Absolutely! The

- With two or three sides for easy access,

- With four sides for maximum containment,

- or even just with the base to quickly move bulky objects.

How to move many rolls in a row together?

Of course, it is possible! To move multiple roll containers like a little train, there are special towing kits that can be welded to the base of the rolls. This way you can connect rolls one after the other and easily transport them with an electric trolley.

Remember to mount the drawbar on the first roll, so it can be hooked to the handling vehicle and the others will followt!

How to transport small goods?

Smaller goods also find a place in Roll Containers, just by taking a few precautions.

- Choose rolls with dense mesh (5×5 cm) to avoid side drops and be able to make maximum use of vertical space, placing a shelf every 5/10 cm if necessary.

- Use polyfoam or fabric covers to better contain the smallest items.

- Place plastic containers (bins or bac) on the shelves so that space is divided and order is maintained during handling.

Is the Roll Container suitable for picking?

The Roll Container is the quintessential king of picking. Italiana Contenitori produces specific

You can always request customization for the roll picking according to the specific needs of your warehouse or business.

Can a Roll Container be used for long-term storage?

Absolutely! Roll Containers are also a practical solution for prolonged storage: thanks to the wire mesh structure and the possibility to close them with 4 sides, lids and safety accessories, they allow you to protect the contents and keep them well organized even for long periods.

Ideal for seasonal storage, inventories, archives or sensitive materials, Security models with tight mesh and padlock closure provide order, visibility and protection, even in shared or frequent handling environments.

Workplace Safety with Roll Containers

How to load a Roll Container?

To properly load a Roll Container, it is important to distribute the weight evenly and maintain load stability. Here are some best practices:

- Load heavier objects down to lower the center of gravity and reduce the risk of tipping.

- Distribute the weight evenly between the two side walls (neither all to the right nor all to the left).

- If the Roll has intermediate shelves, use them to separate goods and optimize vertical space, always keeping the heaviest items at the bottom.

- Use straps or locking accessories to secure the load and keep it stable during transport.

- Avoid overloading: never exceed the maximum load capacity of the Roll (generally between 250 and 600 kg), so as not to compromise the safety and durability of the trolley.

Is it better to push or pull?

Better to push. Always!

Pushing a Roll Container is much safer and more ergonomic than pulling it. Here’s why:

- Total control: by pushing the roll you have a complete view of the path and more control over direction and speed.

- Reduced effort: pushing involves the strongest muscles in the body (legs and torso), while pulling strains the arms and back, increasing the risk of injury.

- Reduced risk of accidents: by pulling, the roll can bump your ankles or get out of hand, while by pushing you are always behind the load and can take action if there are obstacles.

The only exception? Narrow spaces or very tight turns, where you may need to pull for a few meters. But the rest of the way, push!

Is it easy to tip over a roll container?

A well-designed and well-used roll is stable, safe, and reliable, but safety also depends on how you load them and what kind of floor you use them on.

Here’s what can cause rollovers:

- Unbalanced load: heavy objects placed on top or only on one side make the roll unstable.

- Brakes not activated during transport on vehicles: risk of moving roll while vehicle is proceeding.

- Moving on steep ramps or uneven floors: can throw the roll off balance. Proceed with caution on uneven surfaces.

Roll on non-smooth pavements?

Roll Containers can also be used on uneven pavement, such as asphalt, rough concrete or industrial floors, as long as they are equipped with suitable wheels.

Here’s what to consider:

- Wheel diameter: larger wheels (e.g., Ø 125 mm or 160 mm) better overcome small obstacles and unevenness.

- nWheel material: nylon or polyurethane: ideal for rough surfaces, absorb vibration and improve ride comfort.

Italiana Contenitori can help you choose the right wheels based on your work environment.

Lifting a roll on a forklift?

Moving a roll container on a forklift is possible, but some rules must be followed to ensure safety and ease:

- Use roll containers with reinforced bases designed for lifting with forks.

- Make sure the roll is securely fastened or locked to prevent movement during transport.

- Prefer models with anti-tip bars or safety devices that keep the load stable.

- Always check the load capacity of the forklift and distribute the weight evenly on the roll.

Workplace Safety with Roll Containers

How many shelves can I put in a roll container?

In standard mesh roll, you can generally put up to 3 shelves. In dense mesh models, on the other hand, you can place one shelf every 5 cm, so the total number depends on the height of the roll container-this way you can really add a lot of shelves, adapting the interior space to your storage needs.

Fixed or swivel casters: which is better?

The most common and recommended configuration is two fixed wheels and two swivel wheels with brakes. The fixed wheels provide stability and maintain direction while moving, while the swivel wheels allow easy turning.

However, in special situations such as extremely tight spaces, such as narrow aisles or warehouses with closely spaced racks, and in environments where frequent rotations must be performed, such as assembly lines or mobile workstations, four swivel castors may be preferable to maximize maneuverability. This configuration facilitates quick directional changes, although it may slightly reduce straight-line stability.

Are there solutions to make Roll Containers quieter?

Yes, there are wheels designed to greatly reduce noise when handling roll containers. These wheels are made of materials that absorb vibration and minimize the sound produced by contact with the floor, making the work environment more comfortable and less stressful. Italiana Contenitori offers a wide range of roll container wheels, including silent ones ideal for spaces where acoustic comfort is important, without sacrificing strength and durability. You can find all available options here: silent kit wheels.

Brakes: on how many wheels?

The choice of the number of wheels with brakes depends on the use and safety required. In general, it is advisable to mount brakes on at least two wheels, obviously on the swivel wheels, to ensure stability and prevent unwanted movement when loading, unloading, or parking. In particularly dynamic contexts or on sloping surfaces, it may be useful to have brakes on four swivel wheels for maximum safety. Italiana Contenitori offers several brake solutions that can be adapted to various roll container models, allowing the configuration to be tailored to specific needs.

Covers and inner lining: what are the solutions?

Italiana Contenitori provides polyfoam covers to protect the contents from dust and dirt, providing greater security during storage and transport. For customized or branded covers, on the other hand, it is easy to turn to specialized third-party suppliers who can create customized solutions.

Are there closure systems for Roll Containers?

Yes, roll containers can be equipped with four walls, with a half opening side to provide stability for the cargo. In addition, a lid can be added to further protect the goods during transport and storage. The “Security” versions are particularly suitable for those who need extra protection, thanks to the dense mesh and reinforced locking systems that also allow for the application of an anti-theft padlock.

What is a load-retaining strap and what is it used for?

The load-securing strap is an indispensable accessory for stabilizing and securing the contents inside the roll container during handling. It can be made of elastic material or reinforced fabric, depending on requirements: elastic straps offer greater flexibility by easily adapting to loads of different shapes, while reinforced fabric straps provide a strong and durable grip. In either case, the strap prevents objects from shifting or falling, improving safety and preventing damage or accidents during transport.

What are Roll Container tags or identifiers?

You can personalize your roll containers with metal plaques bearing your company name and address (punched). Also, for easy identification during shipping or in the warehouse, you can add metal document folders where you can insert labels or reference documents. This personalization helps maintain order and prevent loss.

Maintenance: what to do to prolong the life of a Roll Container?

Roll containers are an important investment for your business, so it’s worth taking care of every detail to make them last a long time and always work at their best. Here are a few simple but effective tips to keep your rolls looking good:

Cleaning, maintenance and storage

Regular cleaning

Dust, dirt, and debris can affect the operation of the wheels and the life of the metal structure. Wipe often with a damp cloth or use compressed air to remove any dirt, especially from hidden areas such as the joints and wheels. Avoid harsh cleaners that could ruin zincplating or damage plastic parts.

Checks and preventive maintenance

Check the condition of the wheels, welds, and locking systems from time to time. Replace worn or damaged wheels and lubricate moving parts with specific products. Check that welds are intact and there is no damage or bending that could affect stability.

Proper storage

When roll containers are not in use, keep them in a dry place protected from the elements. If possible, take advantage of disassembly or optimized stacking (leaving one roll assembled and inserting the sides of the others inside, then stacking the bases) to reduce space and protect them from accidental impacts.

How to clean a Roll Container?

Cleaning your roll container regularly is critical to keeping it efficient, safe and durable, especially if you use it for packaged food or delicate materials.

Here’s how to do it, step by step:

- Gather the necessary materials

You will need hot water, mild dish soap, a paper towel or sponge, a brush for stubborn surfaces, a spacious bucket or sink, and if you like, a food-approved disinfectant. - Prepare the roll container

Remove large debris of dirt or material left inside to facilitate cleaning. - Wash the roll container

Soak the parts in warm soapy water, or clean them with a sponge or brush, paying attention to all surfaces, especially in the corners and mesh. For more stubborn dirt, use paper towel to pre-clean affected areas. - Rinse thoroughly

Be sure to remove all soap residue to avoid buildup and bad odors. - Possible disinfection

If the roll container is used to transport food or sensitive materials, you can use a disinfectant certified for food contact, always following the manufacturer’s directions. - Dry completely

Let air dry or wipe dry with a clean cloth to prevent rust or mold growth.

Some useful tips:

- Use only mild detergents; avoid harsh products that could damage the material.

- Clean regularly to prevent the accumulation of dirt and bacteria.

- If the roll container is heavily dirty, repeat the cleaning until optimal results are obtained.

Grease and lubricants in wheels: yes or no?

Roll container wheels generally do not have ball bearings, so the use of grease is not recommended. Grease can attract dirt and dust, accumulating and increasing friction, making it more difficult for the wheels to rotate. In addition, it can cause unwanted slipping and compromise safety during handling. To keep wheels efficient, it is best to clean them regularly and, if necessary, lubricate them with specific light oils that do not leave a sticky residue.

How to check wheel wear?

To check the wear and tear on the wheels of a roll container, first observe the rolling surface: if it is visibly worn, smooth or has cracks, it is time to replace them. Also check if the rotation is smooth or if the wheels are stiff, locked or noisy during movement. Excessive wear and tear can compromise the stability and safety of the roll, so it is important to inspect them regularly and take prompt action to avoid problems during use.

What to do if the Roll Container squeaks or makes noise during handling?

If the Roll Container squeaks or makes noise during handling, the first thing to do is to check the condition of the wheels: they may be dirty, worn, or blocked by debris. A thorough cleaning of the wheels and axle can solve the problem. If the noise persists, check all moving parts and lubricate with suitable products (but avoid heavy grease if the wheels do not have bearings). Finally, check for loose or damaged parts that cause chafing or vibration. Regular maintenance helps keep the roll quiet and functional.

Is it possible to replace only some parts of the damaged Roll Container?

Yes, it is possible to replace only certain parts of the damaged Roll Container without changing the entire structure. The most commonly replaceable parts are:

- Wheels: can be easily changed in case of wear and tear or breakage.

- Side or front walls: if a side walls bends or breaks, a replacement can be purchased and reassembled.

- Shelves: if a shelf becomes damaged, it can be removed and replaced with a new one.

Modularity is one of the great advantages of the Roll Container: it enables targeted maintenance, cost reduction, and lower environmental impact, prolonging product life.

Where should roll containers be properly stored when not in use?

When not in use, Roll Containers should be stored in a way that protects them from damage and premature wear and tear. Here are some best practices:

- In covered and dry places: ideally, store them away from rain and moisture to avoid rust or deterioration.

- Stacked or nested: many models are designed to be stacked or nested inside each other so as to save space when unused.

- On flat pavements: avoid uneven or sloping surfaces, which can deform the structure or put stress on the wheels.

- Away from transit areas: place them in a dedicated area to avoid accidental collisions with vehicles or people.

Good warehouse organization also starts with how you manage rolls when they are not needed: order and protection today, efficiency and durability tomorrow.