In recent years, the process of spot welding with welding robots has changed the welding industry, offering numerous advantages over traditional wire or electrode welding. The tack-welding process melts the material through the application of a high-intensity electric current, creating a clean, strong weld.

Spot welding is distinguished by its precision and reliability, ensuring uniform fusion of material without the need to use filler materials as in the case of wire welding. This process eliminates the risk of material contamination and significantly reduces the possibility of defects in the weld, making it particularly suitable for applications requiring high standards of quality and strength.

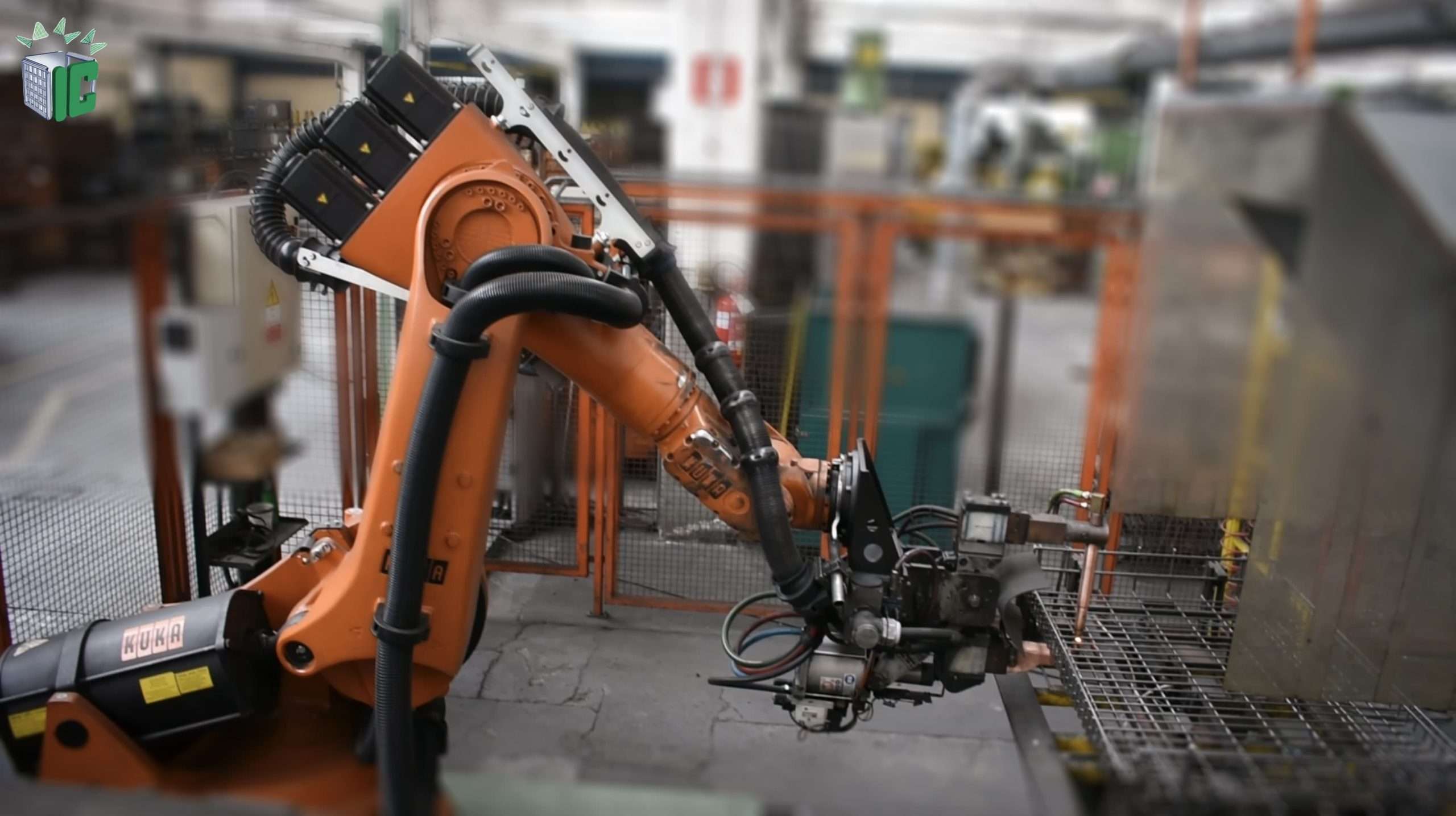

Italiana Contenitori has invested considerable resources in automating the tacking process, purchasing a robot fleet that performs thousands of tackings per day. All welds on IC’s industrial wire mesh containers are made with automatic tackers, ensuring consistent quality and efficient production.

However, it is important to note that some structural welds and other details are made with the help of mechanical welding arms or directly by IC craftsmen in the department. This combination of advanced technology and traditional craftsmanship ensures the highest quality and durability of the containers produced by Italiana Contenitori.

In conclusion, the robot welder spot welding process represents a major breakthrough in the welding industry, offering an efficient, clean and durable solution. Italiana Contenitori is committed to using the best available technologies to ensure the highest quality of its products, thus contributing to the satisfaction and trust of its customers.