We know that in a well-organised warehouse, every inch counts. This is why

Available in sturdy metal, these baskets offer versatility and durability even in complex, high-handling environments. In this article we will look at what makes them so useful, how to choose them based on your warehouse needs, and why they are a smart investment over time.

Warehouse wire mesh cages

Stackable warehouse cagesoffer a number of practical advantages that make them indispensable in industrial, logistics and commercial settings. Their main

- Safety and stability. IC manufactures quality industrial containers designed to ensure perfect stability in stacking, preventing accidental tipping. Some versions also include anti-tip bars or locking systems that ensure tightness even during handling with forklifts or pallet trucks.

- Adaptability to different needs. Stackable cages are available in numerous sizes and capacities: lightweight and collapsible, ideal for logistics, manufacturing, e-commerce, retailers, etc., designed for bulky and heavy loads.

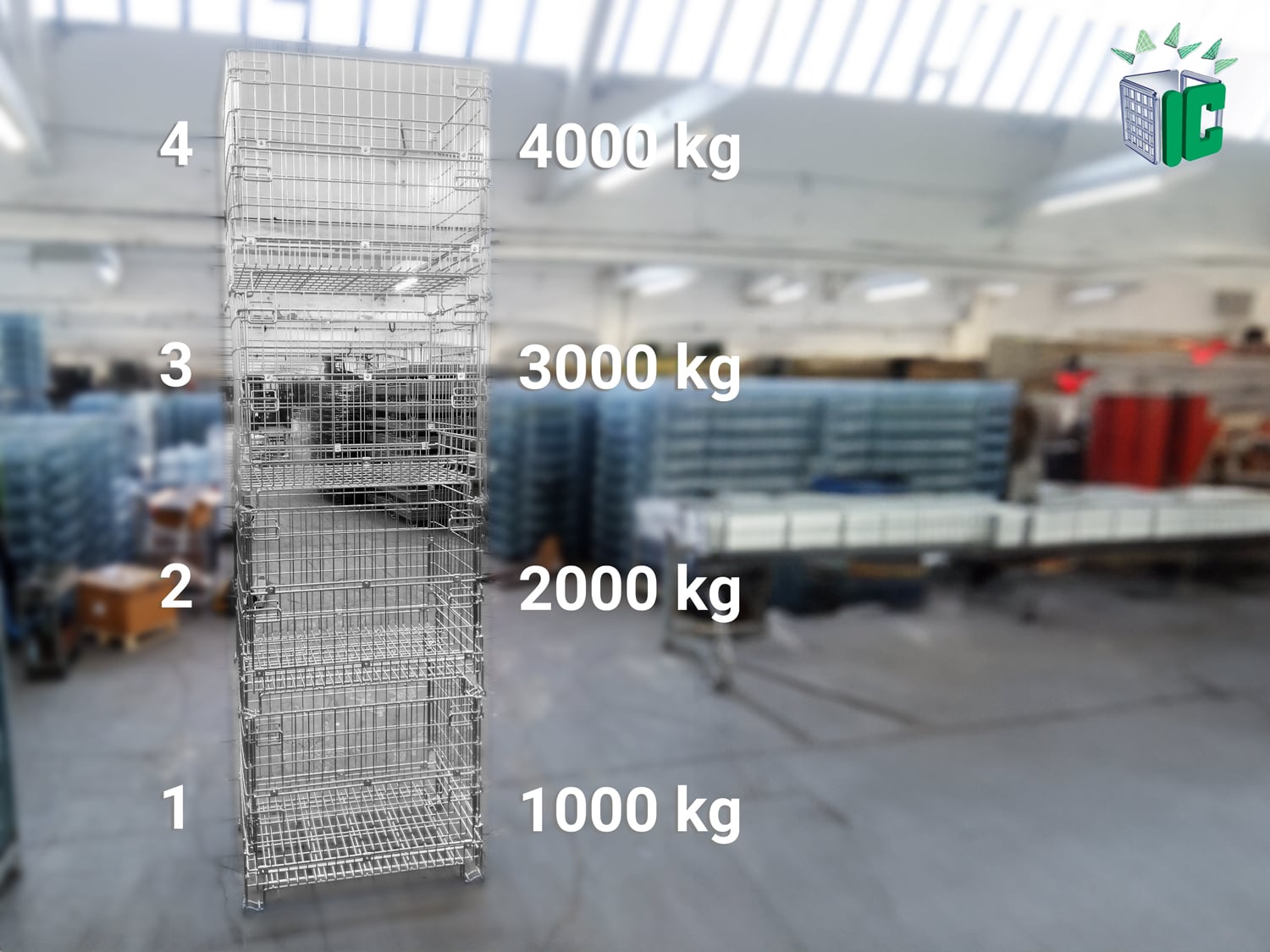

- Optimising vertical space. You can make the most of vertical space while maintaining safety and easy access by arranging the cages one on top of the other. This is especially helpful in warehouses with high ceilings or industrial racking, where maximising vertical space is crucial.

- Increased order and visibility. Stackable cages help maintain an orderly and well-organized warehouse; they are made with a

mesh structure that allowsquick identification of the contents without having to open them, thus speeding up picking and inventory operations. The cages are equipped with one or more doors that allow easy access to the contained material.

Key features of stackable wire mesh storage cages.

Stackable wire mesh storage cages are an ideal solution for those seeking strength, durability and practicality in storage. Here are the main features that make them essential:

- Durable material and structure

Made of electro-welded metal wires with ø between 5 and 6 mm, these cages provide excellent mechanical strength. The wire mesh ensures a strong structure capable of withstanding heavy loads without deforming or being damaged. - High Capacity

Designed to be loaded up to 1,000 kg inside, wire mesh cages are perfect for bulky and heavy materials. Their strength makes them reliable even in demanding industrial settings, where safety and durability are critical. - Stackable, safe and anti-tip bar cages

The design of the cages allows them to be stacked safely, optimizing vertical space in the warehouse. Many models are equipped with anti-tip bars or locking systems that keep the baskets stable even during handling with forklifts or pallet trucks. - Visibility and ventilation

The wire mesh structure allows immediate visibility of the contents, facilitating inspection and inventory management without the need to open the cages. In addition, the mesh allows air circulation, which is ideal for storing goods in humid environments that require ventilation. - Customization: tailor-made stackable cages

Cages can be customized to specific customer’s needs, with options such as internal dividers, lids, labeling systems and different finishes. This flexibility makes them effective logistics solutions that can be adapted to various industries.

Why choose stackable wire mesh storage cages over other solutions?

When it comes to warehouse storage and handling, there are several options on the market, but wire mesh cages offer specific advantages that often make them the best choice for demanding industrial needs.

Superior strength and durability

Unlike many solutions made of plastic or less durable materials, wire metal mesh cages provide a much longer service life even in harsh environments and with heavy loads. Their electro-welded steel construction resists impact, abrasion and adverse weather conditions without warping or breaking.

Increased safety and stability

Ease of inspection and ventilation

The wire mesh allows immediate visibility of the contents and excellent air circulation, features that facilitate goods control, maintenance, and prevention of mold or moisture, aspects often underestimated in closed containers or plastic containers.

A profitable investment in the medium to long term

Versatility of use

| Feature | Metal Wire Mesh cages (Iron) | Plastic Baskets |

|---|---|---|

| Strength and Durability | High resistance to heavy loads and prolonged wear and tear | More prone to cracking and deformation |

| Load Capacity | Suitable for very heavy loads, up to 1000 kg and more | Suitable for light to medium loads |

| Stackability | Stackable safely, often with anti-tip bars | Less stable under high loads |

| Ventilation and Visibility | Open structure for excellent ventilation and visibility | Less ventilation, often closed or partially open |

| Maintenance | Low maintenance, corrosion resistant with treatments | Easy to clean, but deteriorate more easily |

| Weight | Heavier and sturdier | Lightweight and easy to handle |

| Environmental Sustainability | Recyclable materials, long lifespan | Recyclable materials but shorter lifespan |

| Initial Cost | Higher initial investment | Lower initial cost |

| Ease of Handling | Less maneuverable, but often equipped with wheels or pallets | Easy to handle and move |

| Ideal Applications | Heavy industries, logistics, automotive, food | Light warehouses, retail, domestic use |

Sectors and applications of stackable wire mesh storage cages

Stackable wire mesh cages are widely used in a variety of industrial and logistical settings due to their versatility, sturdiness and practicality.

- Manufacturing Industry

Here cages are used to store components, spare parts and raw materials. Their strength and stackability optimize work space and facilitate the movement of goods on the production line. - Logistics and Warehousing

In the logistics industry, wire mesh cages essential for efficient stock management, allowing quick access and visual inspection of contents. Stackable and sturdy, they help maintain order even in high-turnover warehouses. - Food and agribusiness

The ventilation provided by the mesh structure makes them ideal for storing fresh products, such as fruits and vegetables, or materials that require constant air recirculation to maintain quality and safety. - Automotive

In the automotive industry, cages are used to store spare parts, tires, and car body parts because of their ability to handle heavy loads and resistance to stress. - Textiles and Fashion

Wire mesh cages help store textiles, accessories and garments, promoting ventilation and easy identification of items, essential for an organized and functional warehouse.

Discover our range of stackable wire mesh storage cages now and optimize your storage space with sturdy, customized solutions. Contact us now for a free consultation or customized quote!